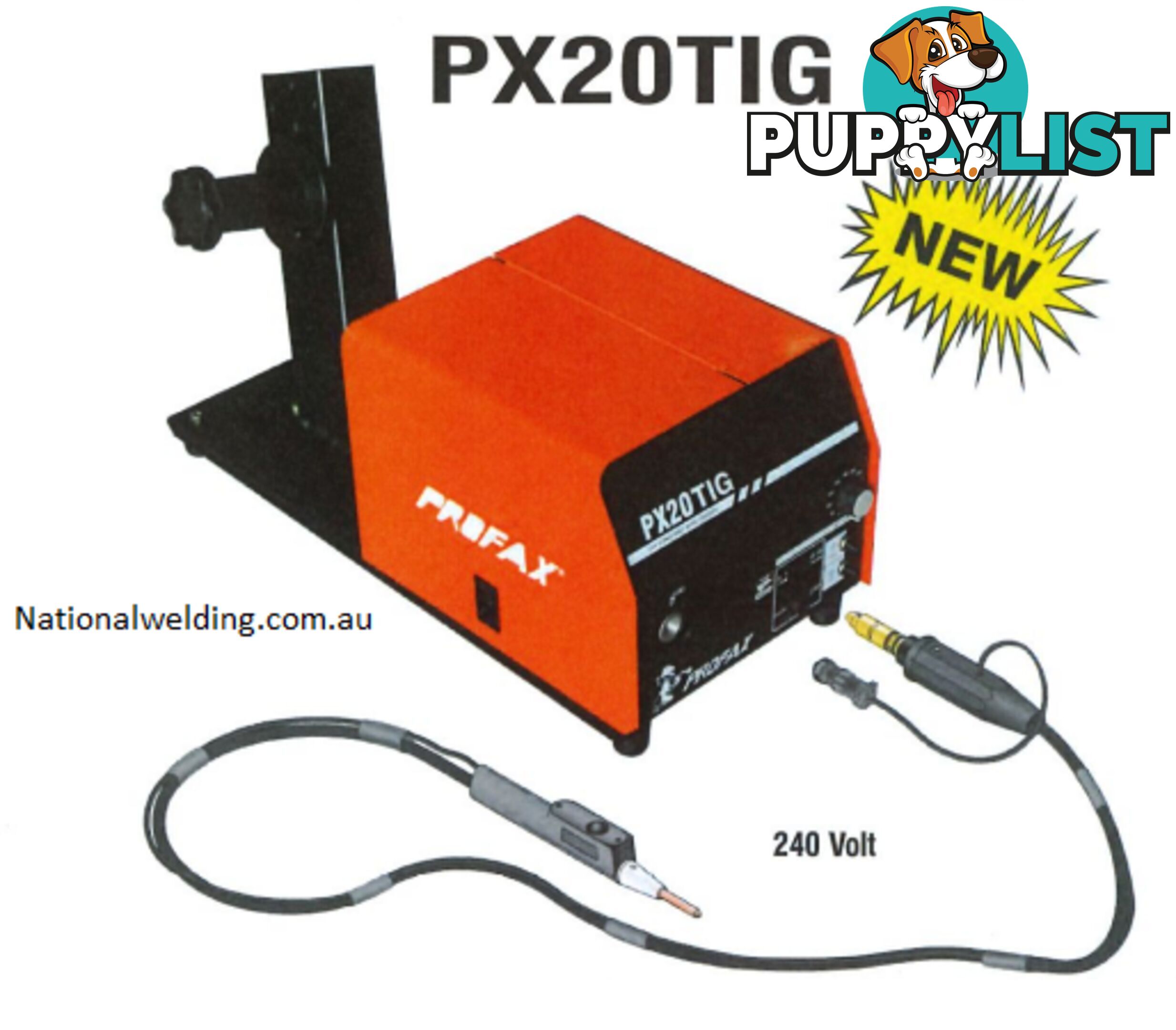

Cold Wire Feeder System for Tig Promax PX20TIG

$2,610.00

DESCRIPTION

COLD WIRE FEEDER SYSTEM FOR TIG PROMAX PX20TIGFeatures:

Improves productivity by eliminating stops caused by cut length wire.

Eliminates end waste of cut length filler metal, an average savings of 10 to 20%.

Reduces cost of filler metal by utilizing spooled wire instead of cut length.

High frequency protection ensures reliability in all TIG applications.

Low initial cost - The PX20TlG is less than half the cost of most TIG cold wire feed systems on the market today

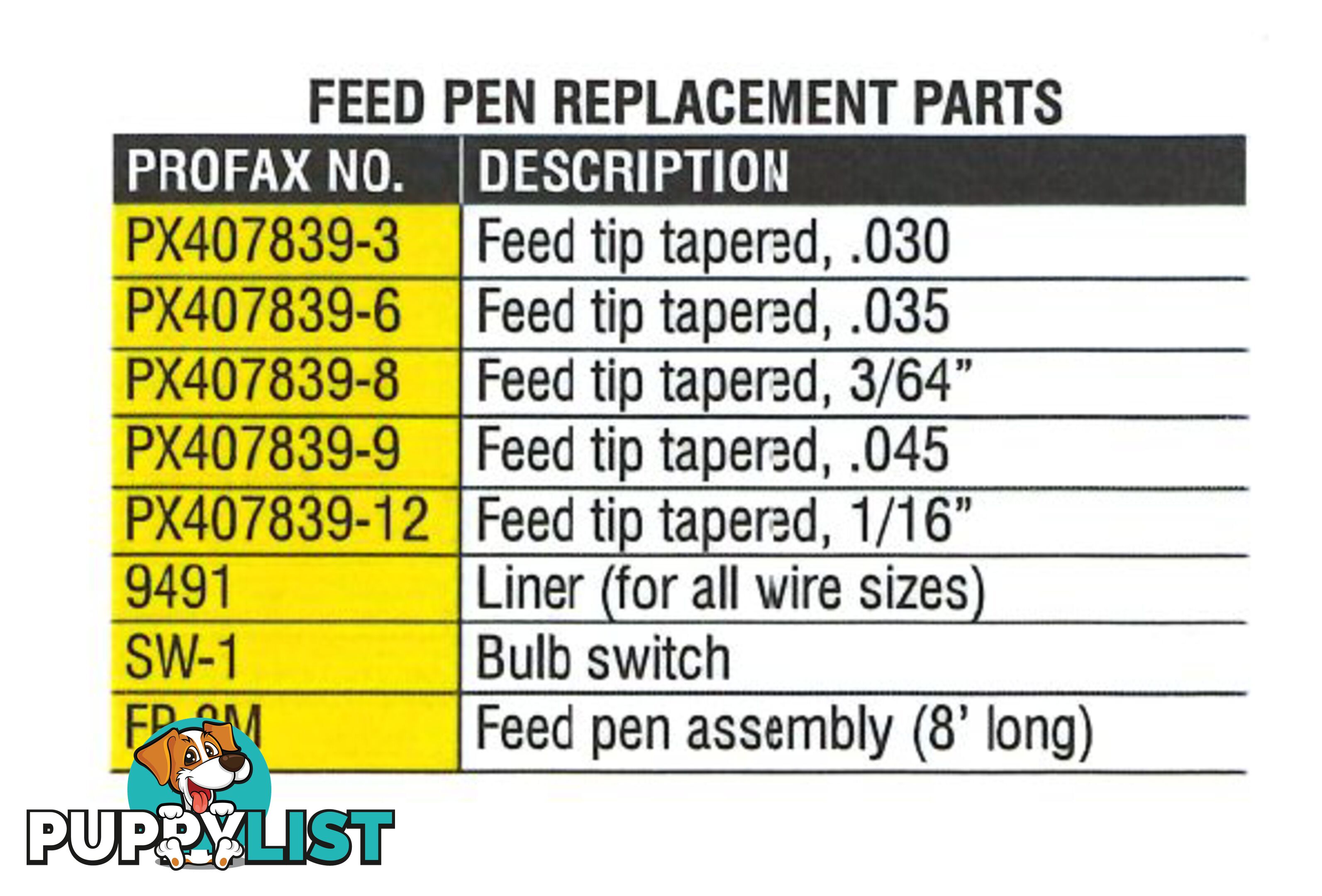

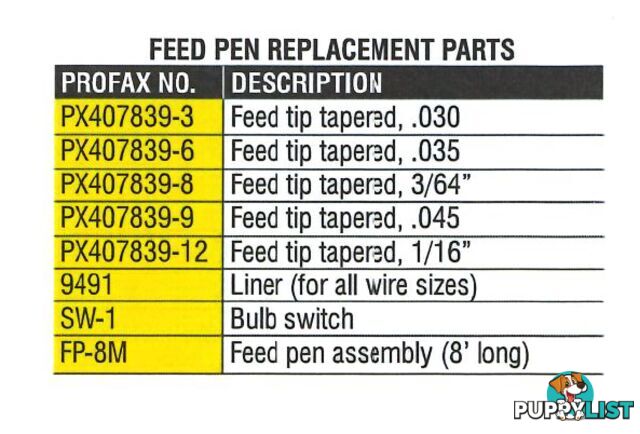

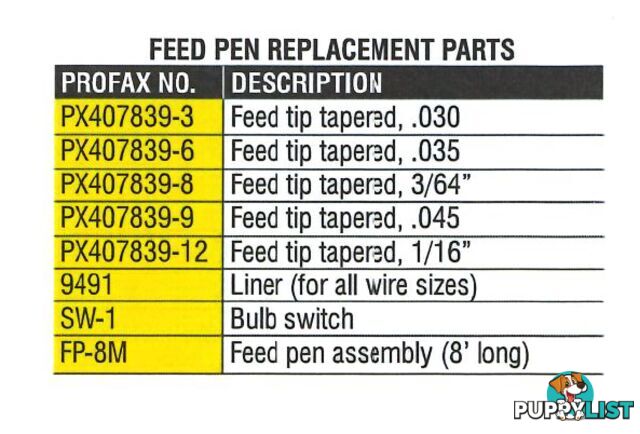

Low operating cost - Utilizes standard feed tips, standard liners, and standard momentary switch on feed pen.

The PX20TIG ships complete - Includes feed pen and 8 lead, drive rolls, power cord and plug for 110VAC input power.

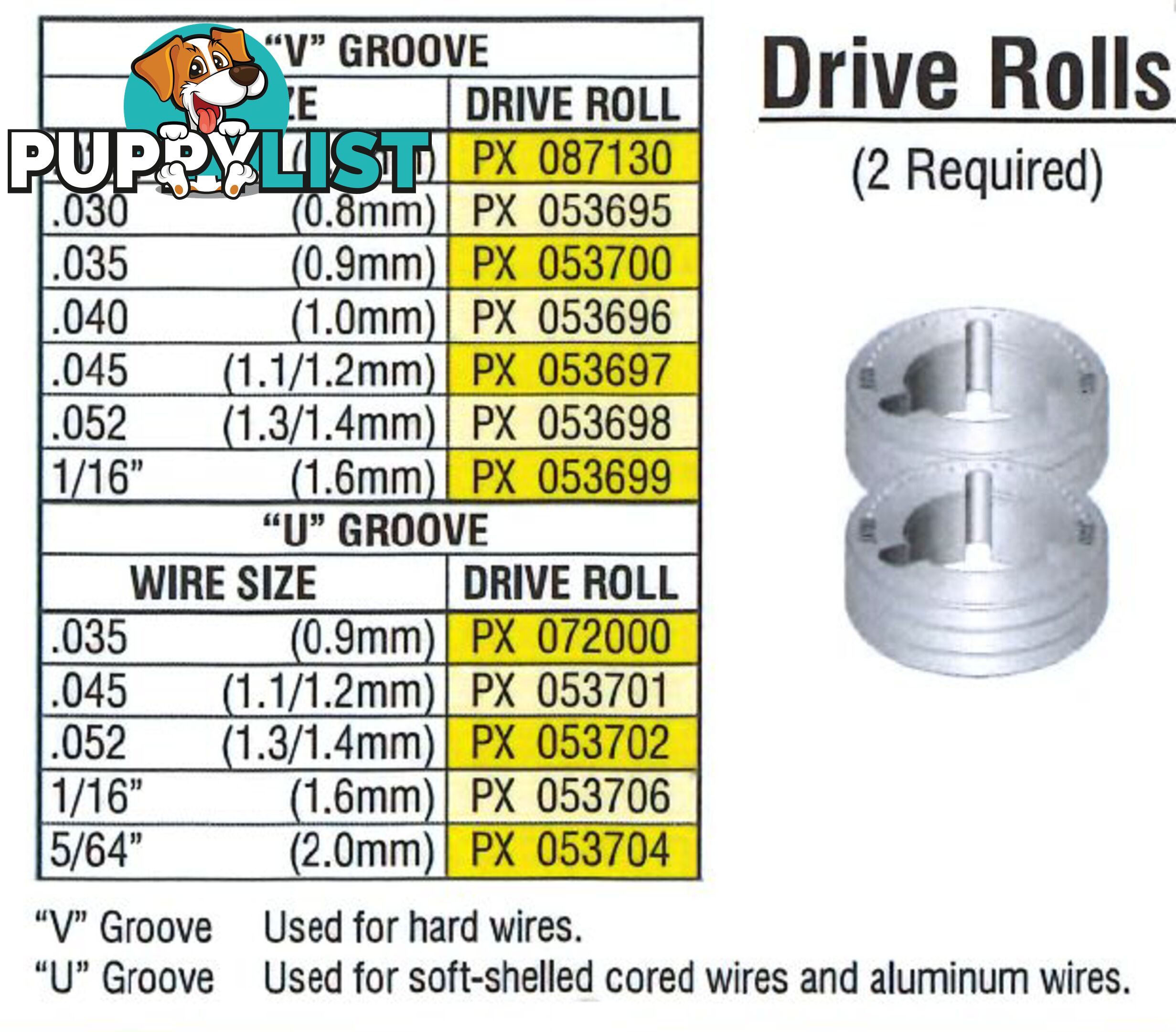

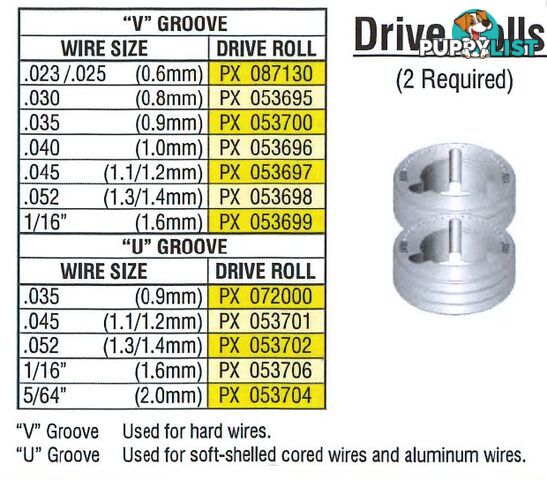

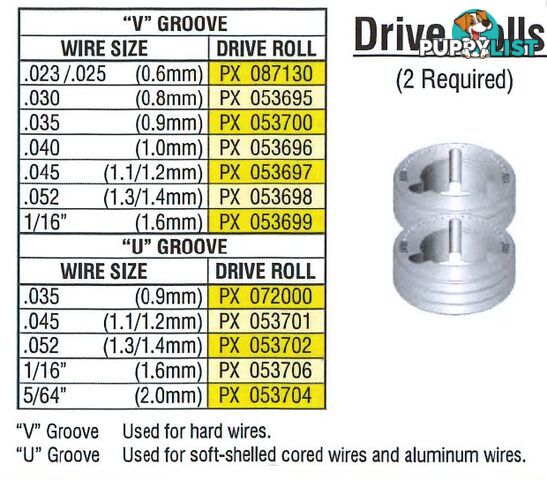

Two (2) gear driven rolls with Tool-Less roll change. (Uses Miller@ style drive rolls).

Spool capacity - Standard 12" spools.

Specifications:

Part # PX-20TIG

Input Power 110VAC (50/60Hz)

Wire Diameters .023" (0.6mm) - 5/64" (2.0mm)

Wire Feed Speed 75 - 900 IPM (1.9 - 23 m/min)

Height 14" (356mm)

Width 11" (280mm)

Depth 25.5" (648mm)

Weight 36 lbs. (16.5kg)

Warranty

3 Year Warranty

Â

Part Number/SKU: PX20TIG

* Product Images are for illustration purposes only, unless otherwise specified colour may be different.

ADDITIONAL INFORMATION

- Price

- $2,610.00

- Location

- Australia

- Condition

- New

- Delivers To

- Australia Wide

National Welding Supplies